The Enexis Group finds itself in an industry prime for innovation stagnation; well-established solutions, a workforce often resistant to change, and heavy regulation on procedures and costs, means that spontaneous innovation is not something that can happen easily. Yet the company has managed to generate hundreds of new ideas each year since 2014, resulting in millions in cost-saving and improved employee safety.

In this exclusive interview, we sat down with Michiel Van Dam – DSO Architect at Enexis – to hear how the company has implemented a strategic approach to operational innovation, and embedded this across the varied divisions that make up the organization. Read on to learn more about this fascinating initiative and understand how you might be able to utilize an idea management platform to deliver similar results for your company.

The Necessity of Growth

Qmarkets: So Michiel, please could you start by telling us a bit about yourself and your role at Enexis?

Michiel: Sure! So Enexis is made up of three distinct divisions, there’s Infrastructure, Asset Management and HR/IT. Within Asset Management we have a team of 12 employees who are dedicated to operational innovation, and I’m one of the leaders within that team.

Qmarkets: Great – and what inspires you most about innovation?

Michiel: What never ceases to amaze me is that, when you meet new people, once you start sharing experiences some kind of magic usually happens. From the necessity of growth the most creative ideas are often formed. And there is always an enthusiasm from people working out their own ideas, the willingness to start small and grow it from there into something amazing.

Qmarkets: Those are certainly principles that also inspire us at Qmarkets! Please could you tell our readers a bit more about Enexis?

Michiel: So right now we’re supplying electricity and gas to around a third of the Netherlands – around 2 million households. 30 years ago all municipalities had their own individual utility suppliers, and gradually they came together and combined until we were left with a handful of utility giants, including Enexis which came from a merger between 10 companies.

We are a regulated, government-owned monopoly that, unlike in the past, only ‘transports’ energy and don’t actually sell it. This means that service quality and efficiency has become our main focus. We pride ourselves on maintaining very high-quality standards and incredibly low downtimes.

Tackling Operational Innovation Stagnation

Qmarkets: Wow, so that’s a pretty unique environment in which to try and cultivate innovation… What kind of challenges are you facing, in both the energy sector and in the Netherlands as a whole?

Michiel: Right. Well you could actually say that we’re in a perfect environment for innovation to stagnate! We have a lot of well-established solutions that haven’t been changed in many years, are heavily regulated, and our infrastructure department – 80% of our workforce – is just focused on doing their jobs predictably. So whilst operational excellence is important, there isn’t much room for doing things differently. It’s also often very dangerous work with rigorous safety regulations, so not the ideal environment for spontaneous innovation.

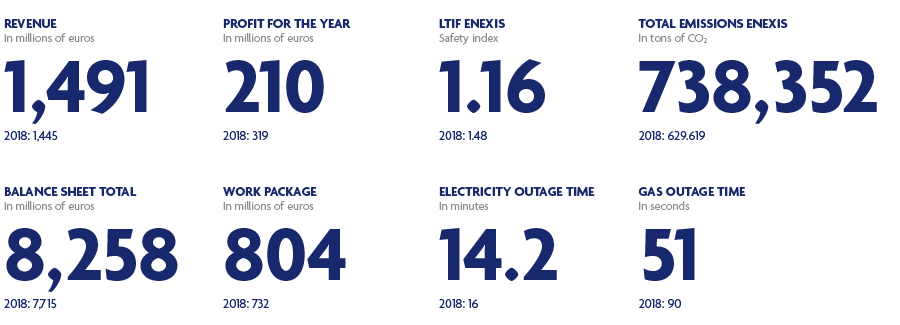

Key Figures About Enexis Group

An additional challenge is our aging workforce which has an average age of 54 or 55, with an even higher average age when it comes to our manual front-line employees. This means that whilst they have lots of valuable experience, they are usually less open to change.

Our company is now subject to a much more rapidly changing environment than in the past. Households’ energy demands are changing and we’re in the midst of an energy transition trying to connect huge amounts of windmills and solar fields. And on top of all this, our regulator also demands a cut in costs every year.

Taking a Dedicated Approach to Operational Innovation

Qmarkets: I see, so those challenges really make it more important than ever to take a dedicated approach to innovation. How have you handled innovation and specifically idea management in the past?

Michiel: Originally we had a post-box where ideas were dropped and an anonymous guy in HQ would say yes or no – mostly no. But this wasn’t engaging and employees were left dissatisfied. Pushing innovation to the workforce was also met with a lot of resistance and didn’t solve their needs.

We realized that our employees have the best ideas for how to improve their own work and needed a dedicated tool to handle this process, so we migrated all of our post-box ideas over to the Qmarkets platform. We now ask our employees for their ideas and let them discuss, and grow their ideas in a transparent and constructive manner.

Qmarkets: Great, and I understand you’ve been with Qmarkets for a long time now – originally becoming a customer in 2016. What made you choose us over the other alternatives?

Michiel: Well since then the project has changed hands several times, I can’t say for sure, although I know we originally looked at a lot of vendors. What I can say is that we chose to renew with Qmarkets last year because we were very happy with what we had achieved and how it served our needs.

In the last four years we have saved several millions of euro’s and increased safety thanks to our employees initiatives.

Qmarkets: Cool, so please could you tell us about the process you’re employing? How does an idea travel through your system?

Michiel: Sure, we start by inviting our colleagues to share and post their ideas and collect them within either a large ‘random ideas’ suggestion box or a specific problem box. These ideas are then placed into 1 of 20 categories, and each of these has an internal department associated with it. We encourage the users to comment, enrich, and ‘like’ the ideas, before passing them all to an ‘evaluation team’ within the relevant internal department. From there they decide whether to prototype an idea, reject it, or perhaps just implement it straight away.

Regardless, the original idea submitter is always involved throughout the whole process. If we ever reject an idea, it’s important for us to make sure the submitter can see the exact reason why and learn from it. Recently we’ve also started launching individual idea challenges focusing on specific strategic topics.

Qmarkets: Ok that’s interesting – and what kinds of results are you seeing from this?

Michiel: So just to share some numbers with you. Out of our 6,000 users we’ve seen 4,000 login, and 3,000 of them are considered engaged. 1,200 ideas have been submitted since September 2014, and we’ve received 7,300 comments and 9,400 total votes. We receive around 200-300 ideas every year, and roughly 25% of those are actually implemented. The ideas all vary in impact, size, and scale. In the last four years we have saved several millions of euro’s and increased safety thanks to our employees initiatives.

Celebrating Employee Ideas

Qmarkets: Wow those are some very impressive numbers, both in terms of engagement and implementation. What’s your secret?

Michiel: Well first of all we have a very prominent placement in the homepage of our intranet. Thanks to Qmarkets integration, everyone sees the “Top 5 recent ideas” whenever they login, so that’s a very big factor.

In addition, every year we have a contest to find that year’s best-implemented idea in our ‘Best Idea of Enexis’ competition. This takes place in a large auditorium with senior management as the jury, and everyone who has an idea in the final top 5 gets their share of recognition. The final winner receives a small statue and appears in the company magazine. This is our way of showing thanks and making sure the idea gets the recognition it deserves.

Qmarkets: So you only use ‘soft’ rewards such as recognition rather than any cash incentive?

Michiel: That’s right yeah. Before we started using Qmarkets we used to incentivize participation by offering 10% of savings generated by an Idea. But we saw that people tend to get very protective over their ideas and kept their ideas to themselves, which also resulted in less collaboration. When we switched to Qmarkets we received way more ideas than in the postbox, even without offering cash.

Improving Communication Between Working Cultures

Qmarkets: What kind of challenges do you face?

Michiel: Well Enexis is actually split up in to 10 regional companies spanning the Netherlands. Even though they were fully integrated into Enexis a long time ago, we still see cultural differences between them. An idea in Groningen for example might not work in Emmen, but it might have already been implemented in Maastricht. One of the reasons for having the Qmarkets platform is to remove these siloes and ensure that ideas flow more easily from one department to another. The platform has improved our communication and turned idea sharing into a standardized practice.

“Our approach relies heavily on the time and effort our operational colleagues can put into innovation, and in ensuring they are allowed to spend this time next to their traditional role is our main challenge.”

Our approach relies heavily on the time and effort our operational colleagues can put into innovation, and in ensuring they are allowed to spend this time next to their traditional role is our main challenge. We need to quantify impact, be it monetary, increased safety or less power outages in terms also relevant for line management.

Looking at top 5 best ideas in last few years we’ve seen good savings in euros and safety. However, one metric not yet measured is employee satisfaction and happiness, we’d like to find out if our employees feel happier with their work now that it’s more easy to share ideas and see them realized.

The Future of Innovation at Enexis

Qmarkets: Wonderful, so what are your plans looking ahead?

Michiel: In our conservative, operational excellence oriented environment, we constantly need to prove the value of innovation and challenge the status quo, but at the same time try to direct our innovation efforts to the issues that matter most to our stakeholders. One of the main changes we’re now making is introducing a campaign-based approach.

We currently have 2 campaigns running – one focusing on ‘DigiTrain’, which is capturing ideas generated during a company-wide training on the digitalization of processes to make work easier.

The other campaign is about getting more value out the millions of sensors and measurements we have monitoring our electricity and gas distribution grid. By engaging our workforce in generating and validating ideas we expect to have not only more ideas but also ones that are more easily adopted.

Regardless, we believe the Qmarkets platform has a large part to play in the future of innovation at Enexis!

To discover how Qmarkets can help you drive employee innovation at your enterprise, and provide the right crowdsourcing platform for your needs, contact us for a free demo today.