The 2019 Summer of Sports has finally arrived, with the Cricket World Cup in full swing, the FIFA Women’s World Cup just beginning, and a plethora of other major global competitions on the horizon. In these elite matches where victory can often be decided by a difference in millimeters or milliseconds, the power of continuous improvement—or ‘incremental innovation’ as it’s sometimes called—is obvious.

Similarly, in business, it’s easy to forget that titans like Toyota and Xerox rose from anonymity to greatness via a series of gradual changes implemented consistently and strategically over time. Continuous improvement has the power to drastically improve efficiency, enhance employee and customer satisfaction, and drive major growth. Considering the disruption faced by companies across the entire landscape of modern business, this is a practice which large companies cannot afford to ignore.

If you’re not familiar with the concept of continuous improvement, it might help to look at another example from the world of sport. Sir Donald Bradman was considered a mediocrity when beginning his test career. Over time, Bradman focused on developing his batting technique – studying the opposition and making incremental changes in stance, grip, and swing. The unique ‘crooked’ technique that Bradman developed as a result led to him becoming recognized as one of the greatest players in history.

Concentrated efforts informed by gradual changes and a strong team focus. Just as in sport, these elements are crucial for maintaining long-term business success.

In this article, we’ll explore four key continuous improvement methods you can put into play to drive success – whether you’re a CEO, Quality Assurance Officer, or a budding athlete.

Perpetual People Power: The Benefits of Continuous Improvement

Continuous improvement, also known as performance excellence, is just what it sounds like – the practice of incrementally enhancing the performance of a company’s products, processes, and services. Terms like ‘operational excellence’ and ‘process excellence’ are frequently used interchangeably with Continuous Improvement – but this is incorrect. While ‘Operational excellence’ refers to the mindset employees and managers must cultivate to generate improvements, ‘process excellence’ deals with how internal corporate processes can be optimized. Think of continuous improvement as an umbrella term that incorporates both.

In the same way that an effective game plan or training regimen will bring the best out of an athlete, an effective continuous improvement process can enable a company to achieve similar results.

Of course, there’s no stock-standard way of ‘doing’ continuous improvement. You’ll need to develop a solution that is aligned with your specific business objectives, capabilities, and culture. To help you get an understanding of what this might be, we’ve prepared a rundown of some of the most popular continuous methodologies in use today.

4 Continuous Improvement Methods for Long-Term Success

1. The Kaizen Method

Combining the Japanese words for ‘change’ (Kai) and ‘good’ (Zen), the Kaizen process entails making small, manageable changes to achieve large-scale benefits over time. The concept can be traced back to post world war two Japan – a time of crisis, when the country was facing a crushing lack of raw materials, investment funds, and morale. American industrialists and manufacturing experts, tasked with assisting Japan with her rebuilding efforts, offered a variety of process-focused optimization strategies to the country’s fledgling industries. Their strategies, combined with Japanese ingenuity, tenacity and waste-reducing attention to detail, helped optimize the development of Kaizen – a strategy based on an existing Japanese concept for maximizing improvements that helped spark the country’s ‘economic miracle’, and made the continuous improvement methods of companies like Toyota famous worldwide.

Although it’s one of those malleable concepts that can vary depending on application, Kaizen as a continuous improvement method can be boiled down to 4 steps, each beginning with an S:

- See – identify how time and resources are used inefficiently

- Solve – harness employee knowledge to determine how these inefficiencies can be improved gradually

- Standardize – formulate ways that proven solutions can be applied to other areas of the company

- Sustain – consistently re-assess solutions to ensure they are still effective

The effectiveness of Kaizen lies in its ability to foster a meticulous attitude to problem solving, while giving employees a role in driving the process of change within an organization.

2. The Total Quality Management Process

To get the most out of a team, a good coach will constantly be on the lookout for ways to augment strengths and sharpen formations. In the same way, a good corporate leader will cast as wide a net as possible when cultivating quality improvement.

This ‘wide net’ approach is embodied in the Total Quality Management (TQM) continuous improvement method. It involves creating a company-spanning environment where all employees are held accountable for quality, while being supported by the tools and training needed to meet their obligations. TQM also involves the regular reassessment of internal guidelines used to regulate quality and streamline workflows.

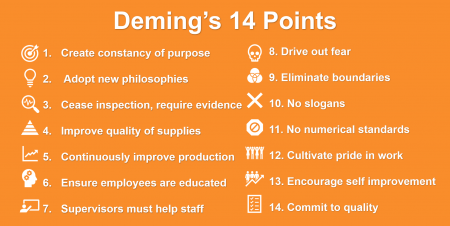

TQM was developed by famous American statistician William Deming – one of the experts who helped spark economic revival in Japan during the post-war period. Deming claimed that American manufacturing was threatened by inconsistency factors – such as uneven part-sizes and conflicting delivery times. To combat this, Deming proposed a 14-point system companies could use to achieve greater consistency around continuous improvement targets:

Global print giant Xerox provides a great example of the effectiveness of the TQM method. The company was able to efficiently reduce its supplier base, cut manufacturing costs by 50%, as well as decrease quality issues by roughly 67% as a result of its TQM-informed standards benchmarking system.

3. The Plan-Do-Study-Act Method

There can be no excellence without experimentation. Olympic high jump gold medalist Dick Fosbury proved this indelibly in the 1960s. Rather than approach the bar with the traditional ‘straddle’ or ‘scissors’ technique, Fosbury ran at an angle and leapt backwards. The winning ‘Fosbury-Flop’ he pioneered continues to be used today.

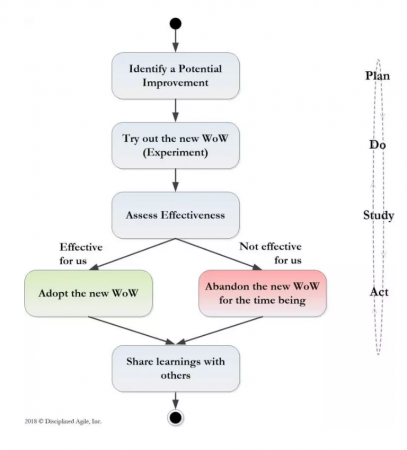

Continuous improvement strategies should likewise leave plenty of room for experimenting with bold ideas. Not only do employees need to be encouraged to think outside the box and provide suggestions for new Ways of Work (WoW), managers need to have a repeatable system in place to measure the results that idea experimentation achieves. This is where the Plan-Do-Study-Act (PDSA) method steps up to the plate.

Also developed by William Deming, the PDSA model offers a clear overview of how new ideas should be optimally incorporated within an organization. After an employee has submitted an idea for where an improvement can be made, the relevant management personnel will create the space required to test it. The results of the experiment are then analyzed based on pre-established criteria. Finally, the ideas that prove viable are adopted, and the learning outcomes shared throughout the company.

The PDSA presents an effective means of removing the element of ‘analysis paralysis’ that can arise when deciding on a continuous improvement strategy. By getting a clearer picture of what doesn’t work in the experimentation process, companies can better approximate what does more rapidly.

4. The Lean Method

Billy Beane is considered one of the most influential managers in the history of baseball, but not just for winning games. In the early 2000s, faced with a restrictive budget and battling a bad average, Beane launched a bold recruitment system. He composed his team, Oakland Athletics, with players with the best stats that had only just fallen short of being recruited by wealthier teams. Selecting the cheapest players with the most talent, Beane both revolutionized baseball management and lead Oakland Athletics to achieve one of the longest winning streaks in American League history.

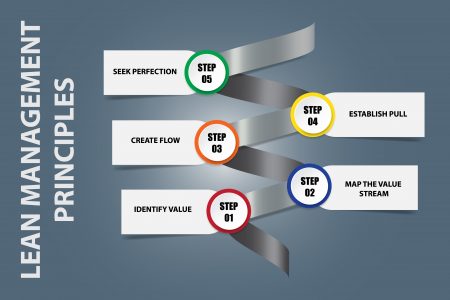

The approach behind Beane’s success is the same one that makes Lean one of the most effective continuous improvement methods: doing more with less. In a nutshell, a Lean business model is one that is geared towards maximizing value with existing resources, while minimizing waste. It involves:

- Determining End-Value: Gaining a thorough understanding of target consumer needs, and gearing all internal improvement activities to meet them

- Mapping Processes: Analyzing the stages a product or service goes through before it reaches the consumer

- Optimizing ‘Flow’ and ‘Pull’: ‘Flow’ refers to how smoothly a product or service moves through the processes, while ‘Pull’ refers to the practice of removing only the materials that have been exhausted –reducing excessive inventory

The real strength of the Lean business model is that it reduces uncertainty, presents a clearer picture of how time and resources can best be implemented, and makes striving for perfection more practical.

Taking Continuous Improvement to the Next Level

Choosing one or a combination of continuous improvement methods is one thing. Putting them into action is quite another. It means generating sophisticated metrics on a regular basis at multiple levels, as well as engaging employees and incentivizing them to share their improvement ideas. Most importantly, managing continuous improvement makes it necessary to have an error-proof method for demonstrating the bottom-line results of new initiative.

Fortunately, Qmarkets’ Q-optimize continuous improvement tool can make this process easy, and help you take corporate performance levels to a league of their own. Q-optimize offers an intuitive means for ideas to be collected, collaborated on, assessed, implemented, and analyzed via advanced analytical and reporting tools. Additionally, Q-optimize offers a reliable system for employees to share best practices with different departments, as well as generate feedback that can help refine these practices further.

In the world of business as well as sport, the same rule applies: Small and steady improvements – reinforced regularly – will eventually lead to major wins. Although the process will entail encountering faults and failures, each one will make the focus of continuous improvement that much more precise. As Babe Ruth once said, “every strike brings you closer to the next home run”.

To discover how Qmarkets can help you harness continuous improvement methods for maximum impact, and help you take your enterprise from strength to strength, organize a free demo with us today.